D643H-0.6-DN50,D643H-0.6-DN65,D643H-0.6-DN80,D643H-0.6-DN100,D643H-0.6-DN125,D643H-0.6-DN150,D643H-0.6-DN200,D643H-0.6-DN250,D643H-0.6-DN300,D643H-0.6-DN350,D643H-0.6-DN400,D643H-0.6-DN450,D643H-0.6-DN500,D643H-0.6-DN600,

D643H-0.6-DN700,D643H-0.6-DN800,D643H-0.6-DN900,D643H-0.6-DN1000,D643H-0.6-DN1100,D643H-0.6-DN1200,D643H-0.6-DN1400,D643H-0.6-DN1500,D643H-0.6-DN1600,D643H-0.6-DN1800,

D643H-0.6-DN2000,D643H-1.0-DN50,D643H-1.0-DN65,D643H-1.0-DN80,D643H-1.0-DN100,D643H-1.0-DN125,D643H-1.0-DN150,D643H-1.0-DN200,D643H-1.0-DN250,D643H-1.0-DN300,

D643H-1.0-DN350,D643H-1.0-DN400,D643H-1.0-DN450,D643H-1.0-DN500,D643H-1.0-DN600,D643H-1.0-DN700,D643H-1.0-DN800,D643H-1.0-DN900,D643H-1.0-DN1000,D643H-1.0-DN1100,

D643H-1.0-DN1200,D643H-1.0-DN1400,D643H-1.0-DN1500,D643H-1.0-DN1600,D643H-1.0-DN1800,D643H-1.0-DN2000,D643H-1.6-DN50,D643H-1.6-DN65,D643H-1.6-DN80,D643H-1.6-DN100,

D643H-1.6-DN125,D643H-1.6-DN150,D643H-1.6-DN200,D643H-1.6-DN250,D643H-1.6-DN300,D643H-1.6-DN350,D643H-1.6-DN400,D643H-1.6-DN450,D643H-1.6-DN500,D643H-1.6-DN600,

D643H-1.6-DN700,D643H-1.6-DN800,D643H-1.6-DN900,D643H-1.6-DN1000,D643H-1.6-DN1100,D643H-1.6-DN1200,D643H-1.6-DN1400,D643H-1.6-DN1500,D643H-1.6-DN1600,D643H-1.6-DN1800,

D643H-1.6-DN2000,D643H-2.5-DN50,D643H-2.5-DN65,D643H-2.5-DN80,D643H-2.5-DN100,D643H-2.5-DN125,D643H-2.5-DN150,D643H-2.5-DN200,D643H-2.5-DN250,D643H-2.5-DN300,

D643H-2.5-DN350,D643H-2.5-DN400,D643H-2.5-DN450,D643H-2.5-DN500,D643H-2.5-DN600,D643H-2.5-DN700,D643H-2.5-DN800,D643H-2.5-DN900,D643H-2.5-DN1000,D643H-2.5-DN1100,

D643H-2.5-DN1200,D643H-2.5-DN1400,D643H-2.5-DN1500,D643H-2.5-DN1600,D643H-2.5-DN1800,D643H-2.5-DN2000,气动金属硬密封蝶阀

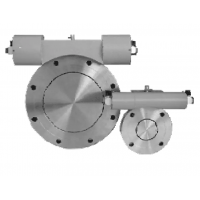

D643H气动多层次法兰金属硬密封蝶阀

严格按照国家GB/T13927-92阀门压力试验标准生产。

采用精密弹性密封圈和三偏心多层次金属硬密封结构,使阀座与碟板密封面均采用不同硬度和不锈钢制作,具有良好的耐腐蚀性,使用寿命长,本阀均有双向密封功能,气动多层次硬密封蝶阀广泛用于

介质温度≤425℃的治金、电力、石油化工、以及给排水和市政建设等工业管道上,作调节流量和载断流体使用。

D643H气动多层次法兰金属硬密封蝶阀性能特点:

1,采用三偏心密封结构,阀座与蝶板几乎无磨损,具有越观越紧的密封功能。

2,密封圈选用不锈钢制作,具有金属硬密封和弹性密封的双重优点,无论在低温和高温的情况下,均具有优良的密封性能,具有耐腐蚀,使用寿命长等特点。

3,碟板密封面采用堆焊钴基硬质合金,密封面耐磨损,使用寿命长.大规格蝶板采用绗架结构,强度高,过流面积大,流阻小。

4,D643H气动多层次硬密封蝶阀具有双向密封功能,安装时不受介质流向的限制,也不受空间位置的影响,可在任何方向安装。气动驱动装置可多工位安装,方便使用。

D643H气动多层次法兰金属硬密封蝶阀执行标准:

制造标准JB/T8527-97

法兰标准GB9113-2000

结构长度标准GB12221-89

检验标准GB/T13927-92

D643H气动多层次法兰金属硬密封蝶阀技术参数:

公称通经DN(mm)50~2000

公称药理PN(MPa)0.61.01.62.5

密封试验(MPa)0.661.11.762.75

强度试验(MPa)0.91.52.43.75

适用温度碳钢:-29℃~425℃不锈钢:-40℃~650℃

适用介质水、空气、天然气、油品及弱腐蚀性流体

泄漏率符合GB/T13927-92标准

驱动方式蜗轮传动、电动、气动、液动

D643H气动多层次法兰金属硬密封蝶阀零件材料:

零件名称材料

阀体WCB、合金钢、不锈钢、QT450-10

蝶板WCB、合金钢、不锈钢、QT450-10

阀轴2Cr13不锈钢、合金钢

密封圈不锈钢圈

填料柔性石墨

D643H气动多层次法兰金属硬密封蝶阀连接尺寸:

公称通径结构长度

(标准值)外形尺寸

(参考值)连接尺寸

(标准值)参考重量

D343H(kg)

LHDd343HDd643HDd943HPN1.6MPaPN2.5MPa

毫米英寸短长H1A1B1H2A2B2H3A3B3DD1Z-dDD1Z-d

502108150112350180200625245725302502551651254-181651254-1819

6521/2112170115370180200625245725302502551851454-181851458-1822

803114180120380180200645245725652502552001608-182001608-1825

1004127190138420180200675355926002502552201808-182351908-2228

1255140200164460180200715355926402502552502108-182702208-2643

1506140210175555270280800355927053003152852408-223002508-2650

200815223020076040042585025017077530031534029512-2236031012-2664

2501016525024383040042592525017094530031540535512-2642537012-3099

300121782702508954505601035450220107030031546041012-2648543016-30130

350141902902809504505601070450220114030031552047016-2655549016-33188

4001621631030511905355801190450220121030031558052516-3062055016-36270

4501822233035012555355801250650280133557571464058520-3067060020-36350

5002022935038013055355801290650280141557571471565020-3373066020-36375

6002426739044513405706601455850380160565681084077020-3684577020-39560

7002829243048015207505501585850380184465681091084024-3696087524-42610

800323184705301710750550170012503802040656810102595024-39108599024-48880

9003633051058018107505501865125038022557858631125105028-391185109028-481100

10004041055065019609007502015125038023807858631255117028-421320121028-561600

120048470630760225010009252250125038026407858631485139032-481530142032-562150

1400565307108502435100092528861685159036-481755164036-623200

16006460079010302780100092531561930182040-561975186040-625000

18007267087012303020110098034212130202044-562195207044-706900

20008076095013503270110098036852345223048-622425230048-709100