BH41W-1.6-DN15,BH41W-1.6-DN20,BH41W-1.6-DN25,BH41W-1.6-DN32,BH41W-1.6-DN40,BH41W-1.6-DN50,BH41W-1.6-DN65,BH41W-1.6-DN80,BH41W-1.6-DN100,BH41W-1.6-DN125,BH41W-1.6-DN150,BH41W-1.6-DN200,BH41W-1.6-DN250,BH41W-1.6-DN300,

BH41W-2.5-DN15,BH41W-2.5-DN20,BH41W-2.5-DN25,BH41W-2.5-DN32,BH41W-2.5-DN40,BH41W-2.5-DN50,BH41W-2.5-DN65,BH41W-2.5-DN80,BH41W-2.5-DN100,BH41W-2.5-DN125,

BH41W-2.5-DN150,BH41W-2.5-DN200,BH41W-2.5-DN250,BH41W-2.5-DN300,BH41W-4.0-DN15,BH41W-4.0-DN20,BH41W-4.0-DN25,BH41W-4.0-DN32,BH41W-4.0-DN40,BH41W-4.0-DN50,

BH41W-4.0-DN65,BH41W-4.0-DN80,BH41W-4.0-DN100,BH41W-4.0-DN125,BH41W-4.0-DN150,BH41W-4.0-DN200,BH41W-4.0-DN250,BH41W-4.0-DN300,BH41W-6.4-DN15,BH41W-6.4-DN20,

BH41W-6.4-DN25,BH41W-6.4-DN32,BH41W-6.4-DN40,BH41W-6.4-DN50,BH41W-6.4-DN65,BH41W-6.4-DN80,BH41W-6.4-DN100,BH41W-6.4-DN125,BH41W-6.4-DN150,BH41W-6.4-DN200,

BH41W-6.4-DN250,BH41W-6.4-DN300,BH41W-10.0-DN15,BH41W-10.0-DN20,BH41W-10.0-DN25,BH41W-10.0-DN32,BH41W-10.0-DN40,BH41W-10.0-DN50,BH41W-10.0-DN65,

BH41W-10.0-DN80,BH41W-10.0-DN100,BH41W-10.0-DN125,BH41W-10.0-DN150,BH41W-10.0-DN200,BH41W-10.0-DN250,BH41W-10.0-DN300,BH41W-16.0-DN15,BH41W-16.0-DN20,

BH41W-16.0-DN25,BH41W-16.0-DN32,BH41W-16.0-DN40,BH41W-16.0-DN50,BH41W-16.0-DN65,BH41W-16.0-DN80,BH41W-16.0-DN100,BH41W-16.0-DN125,BH41W-16.0-DN150,

BH41W-16.0-DN200,BH41W-16.0-DN250,BH41W-16.0-DN300,夹套保温止回阀

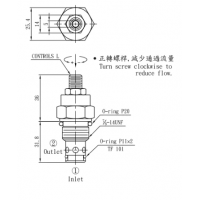

BH41W夹套保温止回阀概述:

保温夹套止回阀主要用于石油、化工、冶金、制药等各类系统中,以输送常温下会凝固的高粘度介质。保温系列阀门的夹套焊装于阀门的两法兰之间,阀门的侧面、底部设置有夹套的连接口。由于增加了夹套,保温阀门的连接法兰尺寸要比同一规格普通球阀的连接法兰大一到两个规格,但结构长度与同规格的阀门相同,夹套中可自由地流过蒸汽或其它热的保温介质,确保粘稠介质可顺畅地流过阀门。

应用范围:

保温止回阀主要用于石油、化工、冶金、制药等各类系统中,以输送常温下会凝固的高粘度介质。

结构特点:

保温止回阀的主要作用是防止介质倒流、防止泵及驱动电动机反转

标准规范:

设计制造标准:GB/T12235、GB/T12236、API6D

结构长度标准:GB/T 12221-2005、ASME B16.10

连接法兰标准:GB/T 9113、GB、HG、JB、API、DIN、JIS

压力温度等级:GB/T 12224-2005

试验检验标准:GB/T 13927-2008、JB/T9092、API598

主体材料:

不锈钢:CF8(304)、CF8M(316)、CF3(304L)、CF3M(316L)、CG3M(317L)、CG8M(317)、CK20(310)

双相不锈钢:S31803(SAF2205,F51、4A、CD3MN)、S32750(SAF2507,F53、6A、CD3MWCuN)

相对应的保温止回阀型号:

BH44W-10P、BH44W-16P、BH44W-25P、BH44W-40P、BH44W-63P、BH44W-100P、

BH44W-150LB、BH44W-300LB、BH44W-600LB、BH41W-10P、BH41W-16P、BH41W-25P、BH41W-40P、BH41W-63P、BH41W-100P、BH41W-150LB、BH41W-300LB、BH41W-600LB

BH41W夹套保温止回阀主要用于石油、化工、冶金、制药等各类系统中,以输送常温下会凝固的高粘度介质。该系列阀门的夹套焊装于阀门的两法兰之间,阀门的侧面、底部设置有夹套的连接口。由于增加了夹套,此种阀门的连接法兰尺寸要比同一规格普通球阀的连接法兰大一到两个规格,但结构长度与同规格的阀门相同,夹套中可自由地流过蒸汽或其它热的保温介质,确保粘稠介质可顺畅地流过阀门

阀体材料:不锈钢(316L、304、CF3M、CF8)、双相钢、 碳钢、钛材

连接形式:法兰式

标准规范

设计与制造 | 配套法兰 | 试验与检验 |

ASME B16.34 GB/T12235、GB/T12236 | ANSI B16.5、JB/T97 | API598

JB/T9092 |

主要连接尺寸

GB 1.6MPa |

DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 650 | 750 |

H | 90 | 95 | 100 | 105 | 110 | 115 | 140 | 170 | 200 | 230 | 255 | 285 | 290 | 300 |

Wt | 14 | 15 | 16 | 17 | 18 | 19 | 24 | 29 | 40 | 58 | 83 | 100 | 105 | 110 |

GB 2.5MPa |

DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 650 | 750 |

H | 90 | 95 | 100 | 105 | 110 | 115 | 140 | 170 | 200 | 230 | 260 | 285 | 290 | 300 |

Wt | 14 | 15 | 16 | 17 | 18 | 19 | 24 | 29 | 40 | 72 | 104 | 145 | 180 | 230 |

GB 4.0MPa |

DN | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 650 | 750 |

H | 120 | 140 | 150 | 160 | 175 | 200 | 225 | 260 | 315 | 320 | 300 |

Wt | 9 | 12 | 15 | 20 | 33 | 41 | 73 | 104 | 147 | 180 | 230 |

GB 6.4MPa |

DN | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 230 | 260 | 300 | 340 | 380 | 430 | 500 | 550 | 600 | 775 | 900 |

H | 160 | 170 | 170 | 190 | 205 | 230 | 265 | 310 | 350 | 480 | 520 |

Wt | 12 | 20 | 29 | 35 | 47 | 68 | 100 | 142 | 195 | 250 | 300 |

GB10.0MPa |

DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 650 | 750 |

H | 90 | 95 | 100 | 105 | 110 | 115 | 140 | 170 | 200 | 230 | 255 | 285 | 290 | 300 |

Wt | 14 | 15 | 16 | 17 | 18 | 19 | 24 | 29 | 40 | 58 | 83 | 100 | 105 | 110 |

GB 16.0MPa |

DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 650 | 750 |

H | 90 | 95 | 100 | 105 | 110 | 115 | 140 | 170 | 200 | 230 | 260 | 290 | 290 | 300 |

Wt | 14 | 15 | 16 | 17 | 18 | 19 | 24 | 29 | 40 | 72 | 104 | 180 | 180 | 230 |