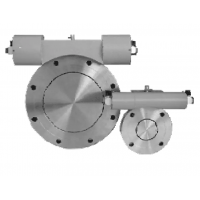

D941H-10C-DN50,D941H-10P-DN50,D941H-10R-DN50,D941H-16C-DN50,电动法兰夹式对夹式硬密封蝶阀

D941H-10C-DN50,D941H-10C-DN65,D941H-10C-DN80,D941H-10C-DN100,D941H-10C-DN125,D941H-10C-DN150,D941H-10C-DN200,D941H-10C-DN250,D941H-10C-DN300,D941H-10C-DN350,D941H-10C-DN400,D941H-10C-DN450,D941H-10C-DN500,D941H-10C-DN600,D941H-10C-DN700,D941H-10C-DN800,D941H-10C-DN900,D941H-10C-DN1000,D941H-10C-DN1200,D941H-10C-DN2000,

D941H-10P-DN50,D941H-10P-DN65,D941H-10P-DN80,D941H-10P-DN100,D941H-10P-DN125,D941H-10P-DN150,D941H-10P-DN200,D941H-10P-DN250,D941H-10P-DN300,D941H-10P-DN350,D941H-10P-DN400,D941H-10P-DN450,D941H-10P-DN500,D941H-10P-DN600,D941H-10P-DN700,D941H-10P-DN800,D941H-10P-DN900,D941H-10P-DN1000,D941H-10P-DN1200,D941H-10P-DN2000,

D941H-10R-DN50,D941H-10R-DN65,D941H-10R-DN80,D941H-10R-DN100,D941H-10R-DN125,D941H-10R-DN150,D941H-10R-DN200,D941H-10R-DN250,D941H-10R-DN300,D941H-10R-DN350,D941H-10R-DN400,D941H-10R-DN450,D941H-10R-DN500,D941H-10R-DN600,D941H-10R-DN700,D941H-10R-DN800,D941H-10R-DN900,D941H-10R-DN1000,D941H-10R-DN1200,D941H-10R-DN2000,

D941H-16C-DN50,D941H-16C-DN65,D941H-16C-DN80,D941H-16C-DN100,D941H-16C-DN125,D941H-16C-DN150,D941H-16C-DN200,D941H-16C-DN250,D941H-16C-DN300,D941H-16C-DN350,D941H-16C-DN400,D941H-16C-DN450,D941H-16C-DN500,D941H-16C-DN600,D941H-16C-DN700,D941H-16C-DN800,D941H-16C-DN900,D941H-16C-DN1000,D941H-16C-DN1200,D941H-16C-DN2000,

D941H-16P-DN50,D941H-16P-DN65,D941H-16P-DN80,D941H-16P-DN100,D941H-16P-DN125,D941H-16P-DN150,D941H-16P-DN200,D941H-16P-DN250,D941H-16P-DN300,D941H-16P-DN350,D941H-16P-DN400,D941H-16P-DN450,D941H-16P-DN500,D941H-16P-DN600,D941H-16P-DN700,D941H-16P-DN800,D941H-16P-DN900,D941H-16P-DN1000,D941H-16P-DN1200,D941H-16P-DN2000,

D941H-16R-DN50,D941H-16R-DN65,D941H-16R-DN80,D941H-16R-DN100,D941H-16R-DN125,D941H-16R-DN150,D941H-16R-DN200,D941H-16R-DN250,D941H-16R-DN300,D941H-16R-DN350,D941H-16R-DN400,D941H-16R-DN450,D941H-16R-DN500,D941H-16R-DN600,D941H-16R-DN700,D941H-16R-DN800,D941H-16R-DN900,D941H-16R-DN1000,D941H-16R-DN1200,D941H-16R-DN2000,

|

产品概述

D941H电动法兰夹式对夹式硬密封蝶阀,采用精密的J形弹性密封圈和三偏心多层次金属硬密封结构,被广泛用于介质温度≤425℃的治金 、电力、石油化工、以及给排水和市政建设等工业管道上,作调节流量和载断流体使用。该阀采用三偏心结构,阀座与碟板密封面均采用不同硬度和不锈钢制作,具有良好的耐腐蚀性,使用寿命长,本阀具有双向密封功能,产品符合国家GB/T13927-92阀门压力试验标准。

|

|

产品特点

1、本阀采用三偏心密封结构,阀座与蝶板磨损小。

2、密封圈选用不锈钢制作,具有金属硬密封和弹性密封的双重优点,无论在低温和高温的情况下,均具有优良的密封性能,具有耐腐蚀,使用寿命长等特点。

3、碟板密封面采用堆焊钴基硬质合金,密封面耐磨损,使用寿命长.

4、大规格蝶板采用绗架结构,强度高,过流面积大,流阻小。

5、本阀具有双向密封功能,安装时不受介质流向的限制,也不受空间位置的影响,可在任何方向安装。

6、驱动装置可以多工位(旋转90°或180°)安装,便于用户使用。

|

|

主要技术参数

|

公称通径DN(mm)

|

50~2000

|

|

公称压力PN(MPa)

|

0.6

|

1.0

|

1.6

|

2.5

|

|

密封试验(MPa)

|

0.66

|

1.1

|

1.76

|

2.75

|

|

强度试验(MPa)

|

0.9

|

1.5

|

2.4

|

3.75

|

|

适用温度

|

碳钢:-29℃~425℃ 不锈钢:-40℃~650℃

|

|

适用介质

|

水、空气、天然气、油品及弱腐蚀性流体

|

|

泄漏率

|

符合GB/T13927-92标准

|

|

驱动方式

|

蜗轮传动、电动、气动、液动

|

主要零部件材料

|

零件名称

|

材 料

|

|

阀 体

|

WCB、合金钢、不锈钢、QT450-10

|

|

蝶 板

|

WCB、合金钢、不锈钢、QT450-10

|

|

阀 轴

|

2Cr13不锈钢、合金钢

|

|

密封圈

|

不锈钢圈

|

|

填 料

|

柔性石墨

|

采用标准

|

制造标准

|

JB/T 8527-97

|

|

法兰标准

|

GB9113-2000

|

|

结构长度标准

|

GB12221-89

|

|

检验标准

|

GB/T 13927-92

|

|